3 wheel A-Series

X Series Reachstacker 45t

Always safe and reliable. It has durable and reliable high-quality key parts of internationally renowned brands and comprehensive safety protection technologies.

Overview

The RS4531CH-XRW86 Reachstacker is a newly developed product based on Hangcha’s X series platforms. Inheriting the appearance of the X series family, it is fashionable, high-end and powerful. Using key parts of internationally renowned brands, it has excellent performance and guaranteed quality.

16,000 – 45,000 KG

Load Capacity

0 – 15200 mm

Lift Height

Diesel

Dirve Types

Product Features

It has strong power system and comprehensive electrical system. Proven energy-saver and efficient.

Detail01

Detail02

Detail03

Detail04

Detail05

Safety technologies such as seat sensing, dynamic antitipping protection, longitudinal dual anti-tipping protection, spreader twist-lock dual protection, startup anti-stalling protection, fault protection, etc. are used to ensure safe operations at all times.

The system is equipped with electro-hydraulic proportional sectional valve of world-renowned brand, silent gear pump, pilot electric control handle, and AC oil pump motor. The load sensing hydraulic system reduces continuous load on oil pump motor; the remote electric control operating mode is simple, easy, and flexible. Several hydraulic pressure detection points are added to simplify maintenance and service work.

Electric proportional control, throttle following control, vertical lift control, intelligent cooling fan control and torque control enable efficient and flexible control.

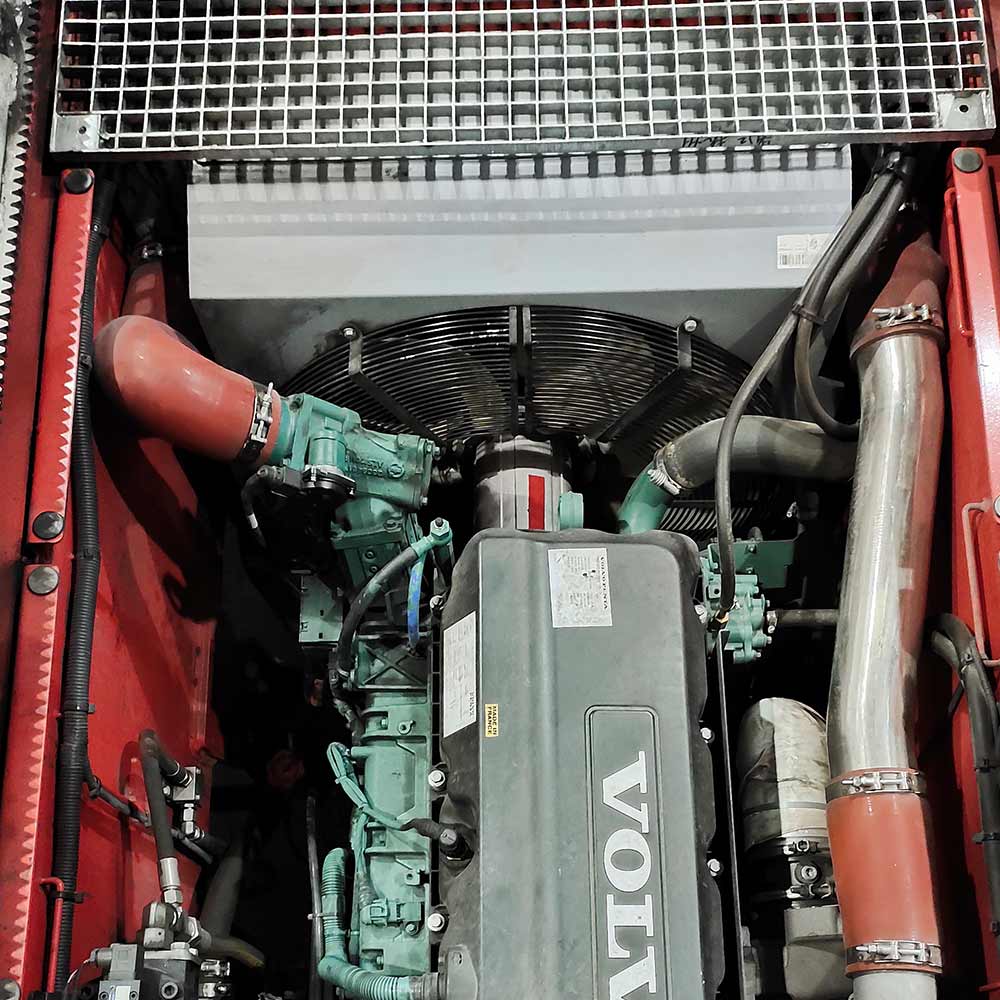

With high performance and low fuel consumption, the low-speed high-torque VOLVO TAD1151VE engine has advanced fault diagnosis and fault protection functions. With a displacement of 10.8L, six in-line cylinders and low emission, it is turbocharged and meets EPA3, EUⅢA and China Stage III emission requirements.

For the new-generation ELME817 series telescopic container spreader, the design of the telescopic beam, turntable, etc. are optimized, so that the structural strength is increased, the weight of the spreader is 16% less than that of the spreader of the last generation and the service life is prolonged by 30%. The arrangement of the oil cylinder is changed.

Fans with electronic motors are used independently to cool hydraulic oil and brake oil, so that the requirements for use in the 50-degree high temperature environment are met. Torque converter oil temperature control management ensures that the gearbox works within the optimal temperature range.

The pitch-down streamlined design of the vehicle presents a vivid and sturdy profile. The optimized counterweight contour greatly reduces the turning radius of the vehicle, broadens the side rear and front rear views, and makes driving simple and safe.

Product Gallery

Grab this stylish and comfortable reach stacker with high-end modelling elements